When customers are looking for a mower to suit a smaller tractor, one of the most common questions asked is whether a slasher mower or a compact flail mower is the better option. While both machines are designed to cut grass, they operate very differently and are suited to different environments and expectations.

In this comparison, we break down how each mower works, what results you can expect, and which option may suit your situation best.

How a Slasher Mower Works

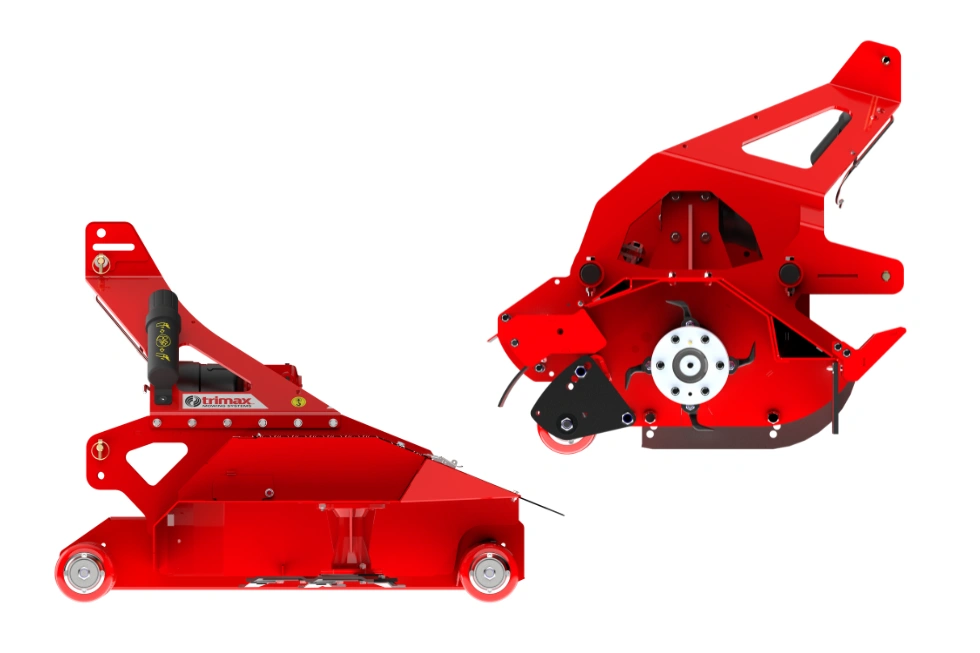

A slasher mower operates using a single large cutting disc, often fitted with two smaller blades at the ends. These blades spin parallel to the ground, working much like an oversized rotary mower you might use at home.

Because the slasher relies on one long blade, the grass being cut has more leverage against the blade and the tractor’s engine. As a result, slashers typically require more horsepower to drive compared to a flail mower of a similar cutting width.

In operation, slashers tend to discharge grass in clumps, often leaving a windrow behind the mower. While this may be acceptable in some situations, it can affect finish quality and may require additional passes to achieve an even result, especially in longer grass.

Slashers are simple machines, which is reflected in their lower purchase price. With a single gearbox, PTO shaft, and blade, they are generally inexpensive to buy and maintain.

How a Flail Mower Works

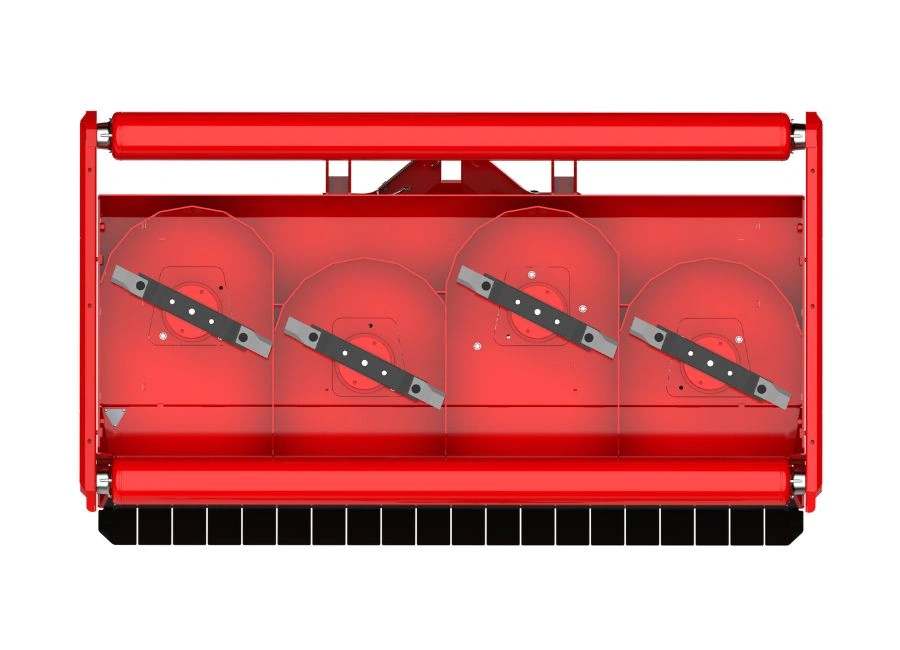

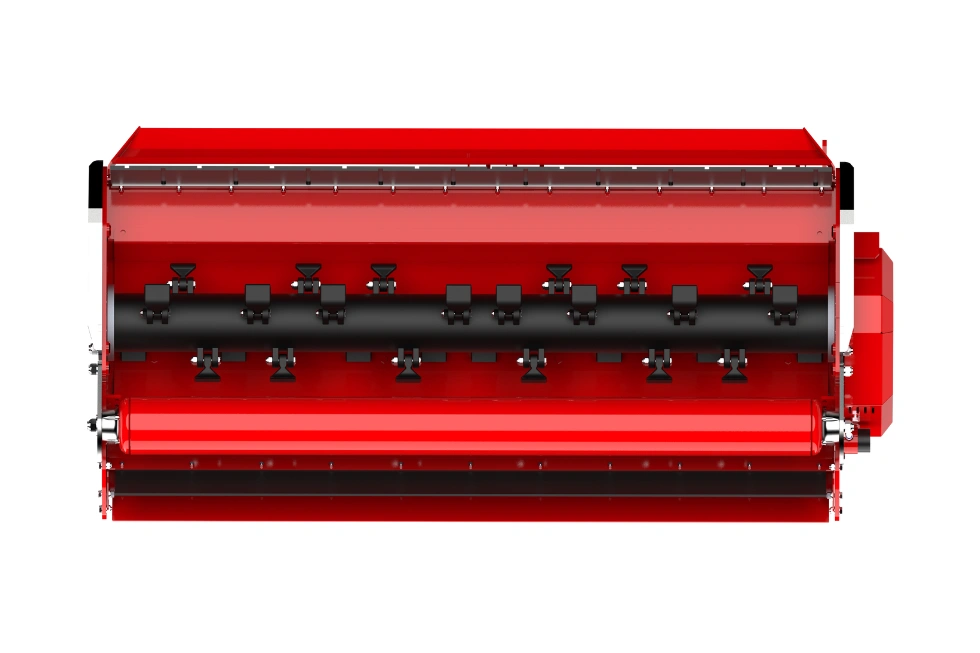

A flail mower operates quite differently. Instead of a single blade, it uses a horizontal rotor fitted with multiple Y-flails or blades spread across the full width of the mower. As the rotor spins, these flails cut and process the material repeatedly before discharging it.

This design means a flail mower requires less horsepower to operate. Because the cutting force is spread across many smaller blades, there is less load on the tractor, resulting in lower fuel consumption and reduced operating costs.

Flail mowers discharge material much finer and more evenly, eliminating clumping and windrows. This produces a cleaner finish and more consistent presentation, particularly in short grass.

Cut Quality and Presentation

In short grass, a flail mower delivers a neat, even finish with excellent clip distribution. Trimax flail mowers ride on a rear roller tucked under the body, preventing scalping and producing a striped finish.

A slasher can also perform well in short grass, but because it rides on skids rather than a roller, it is more likely to damage wet turf. Slashers also tend to leave uneven discharge patterns behind.

In longer grass, the difference becomes more pronounced. Flail mowers process and mulch longer material effectively, distributing it evenly in a single pass. Slashers often struggle in these conditions and may require multiple passes to achieve a similar result.

Performance in Long Grass and Mulching Capability

This is where the flail mower really comes into its own. The cutting action of a flail mower allows long grass to be processed and mulched, rather than simply knocked down. The result is finer material spread evenly across the ground.

The Trimax Ezeemow, for example, is capable of mulching woody weeds and timber up to 25mm (1 inch) in diameter. This means pruning material can often be mulched directly, potentially removing the need for a separate chipper. In many cases, this makes a flail mower two tools in one.

Stability, Safety, and Ease of Use

Flail mowers mount closer to the back of the tractor, reducing weight transfer off the front axle. This improves stability, particularly on slopes. The compact mounting also reduces swing when turning near fences, buildings, or orchard rows.

In contrast, slashers are longer from front to rear, which increases swing radius and removes more weight from the front of the tractor, affecting stability.

Safety is another key consideration. Slashers offer very little containment of discharge, meaning debris can be thrown from the rear of the mower. This requires extra caution, especially around children, pets, buildings, or public areas.

Flail mowers discharge material downward to the ground, significantly reducing the risk of projectiles. This makes them a safer option for public environments, lifestyle blocks, orchards, and areas where people or animals may be nearby.

Cost and Value Considerations

Slashers are simple machines and generally cheaper to purchase. If budget is the primary concern and the finish quality is less critical, a slasher may be a suitable option.

Flail mowers have more moving parts, including multiple blades, belts, and a rotor system. This places them in a different price bracket. However, the added versatility, efficiency, safety, and quality of finish often outweigh the initial cost, especially when fewer passes are required and fuel consumption is lower.

Ultimately, the decision comes down to what you value most: upfront price or long-term performance and versatility.

Watch the full video below for a more in-depth explanation.

Visit our customer success stories to see how Trimax flail mowers perform in real-world applications.